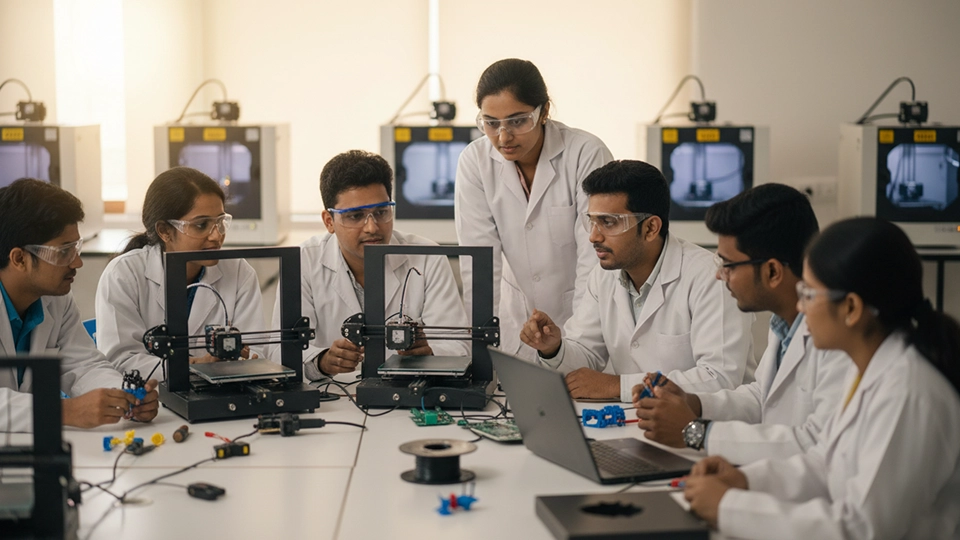

Academic & Research Enablement

Polymer and metal 3D printing systems give students and faculty hands-on learning opportunities that go beyond theory. They allow learners to experiment with real-world designs, develop practical skills, and engage in interdisciplinary projects. These tools integrate smoothly with the curriculum, enhancing student understanding in engineering, design, and materials science while supporting faculty research with precise, repeatable, and complex prototypes.