First Process

Preparing the G-code file.

Design Roots offers expert CNC machining services to industries across India. We create custom parts with high precision using advanced technology. You can count on us for precise, quick, and reliable CNC machining solutions that fit your industry needs.

At Design Roots, Bengaluru, we offer personalized quotations for custom CNC machined parts with competitive pricing. Get in touch with us today and get a quote.

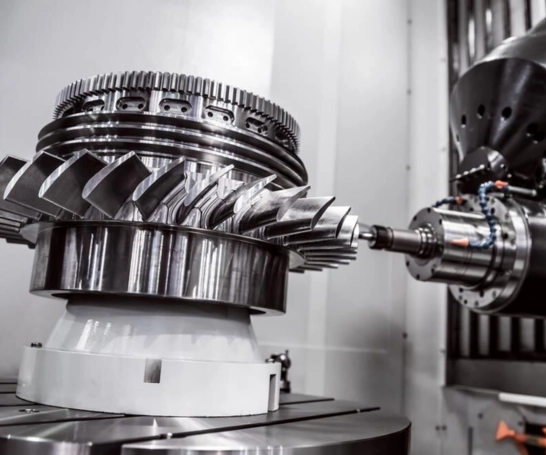

CNC, or computer numerical control machining, is a manufacturing process using automated cutting tools to form designs from metal or plastic stock. Standard machines include milling machines, lathes, and routers. Skilled machinists program tool paths based on part geometry, providing precision and repeatability for various industries. Design Roots offers custom CNC machining for various materials including Aluminium, Stainless Steel, Alloy steel & Titanium.

Design Roots uses advanced 3-axis, 4-axis, and 5-axis CNC equipment to offer machined metals and plastics. Our services include CNC milling, turning, EDM, wire EDM, surface grinding, and more. We also complement our 3D metal printing service making them a one-stop shop for advanced designs. We can deliver machined parts with a finishing service.

We offer top-notch CNC milling services in Bangalore. Our end to end manufacturing process utilizes advanced milling machines to shape materials precisely and efficiently.

Here’s how the CNC milling process works at Design Roots:

We begin by securing a block of metal or plastic material inside the CNC mill.

Our expert team programs the CNC machine to rapidly mill parts from the raw material using G-code.

Machined plastic parts typically retain the as-milled surface, which shows visible tool marks.

For customers who require more refined finishes, we offer additional options for some metals, such as anodizing and chromate plating.

At Design Roots, we’re committed to delivering high-quality CNC milled parts with precision, reliability, and a wide array of finishing options to meet the specific needs of every project.

We also specialize in machining high-performance plastics, such as:

A common thermoplastic with good mechanical properties, impact strength, and heat resistance.

Renowned for its toughness, high impact strength, and good machinability.

An engineering thermoplastic with the highest machinability among plastics, ideal for complex parts.

Preparing the G-code file.

Loading the material into the machine.

Securing the workpiece using the chuck.

Gradually remove material until the desired geometry is achieved.

Cutting the part from the stock for any necessary surface finishes.

At Design Roots, we proudly offer high-quality CNC turning services as part of our advanced manufacturing solutions. CNC turning is a precise subtractive process that involves rotating a metal rod while a cutting tool removes material to form the final part. This process allows us to create highly accurate components with efficiency and consistency.

Our CNC turning process follows five essential steps:

We work with a wide range of metals to meet the specific needs of each project

Aluminum : Popular for its high machinability, lightweight nature, and strength, making it a cost-effective choice.

Stainless Steel : Offers good machinability with added strength and chemical resistance.

Alloy Steel : Known for high fatigue strength, toughness, and impact resistance.

Titanium : The premium choice in CNC turning, offering unmatched strength and durability, but also the most expensive in the metal category.

Design Roots specializes in precision CNC-turned parts, meeting high standards in performance and appearance. We offer expertise, equipment, and finishing options for metal or plastic components, ensuring accuracy and quality in bringing your project to life.

We offer a variety of finishing options to meet both functional and aesthetic requirements:

As-machined : Standard finish (~125 RA µin), with minor tool marks visible.

Anodizing : Adds corrosion resistance, increases surface hardness, and improves heat dissipation.

Painting & Color Matching : Offers precise color matching to standard Pantone shades.

Blasting & Polishing : Produces a smooth, uniform surface for a polished appearance.

Black Oxide : Enhances corrosion resistance while minimizing light reflection.

Vapour Polishing : Provides optical clarity on polycarbonate plastics

Heat Treatments : Includes annealing, carburizing, cryogenic treatment, induction hardening, and nitriding for enhanced material properties.

We follow to complete quality control procedures, which include dimensional accuracy checks, material inspections, and surface finish inspections. Depending on the industry—whether aerospace, automotive, or medical—we follow applicable industry standards and certifications to assure the highest quality in every part we manufacture.