Best 3D Printing & Vacuum Casting Services, Mysore

3D Printing & Vacuum Casting for Rapid Prototyping in Mysuru

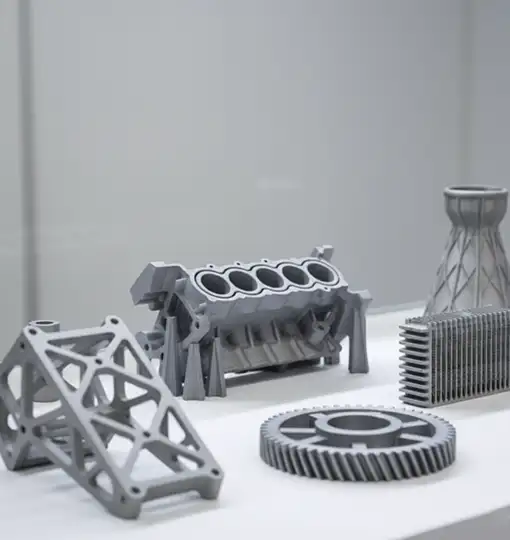

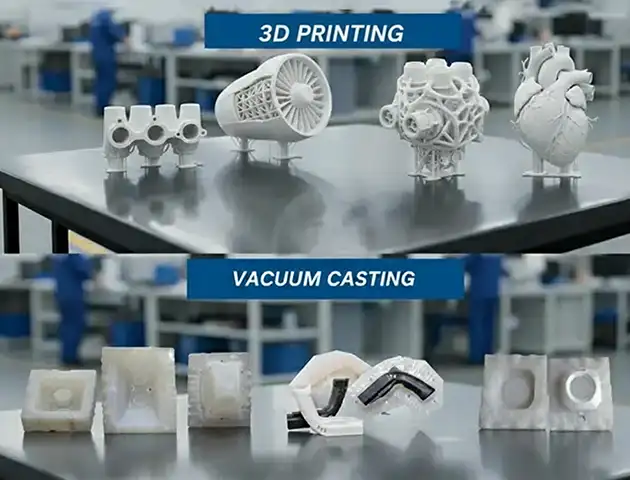

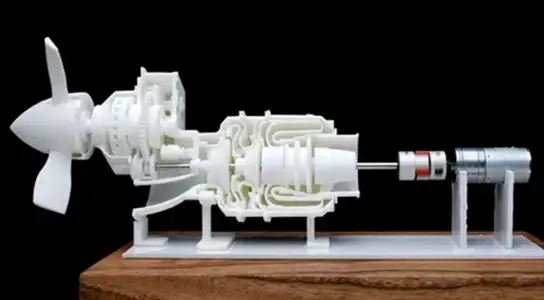

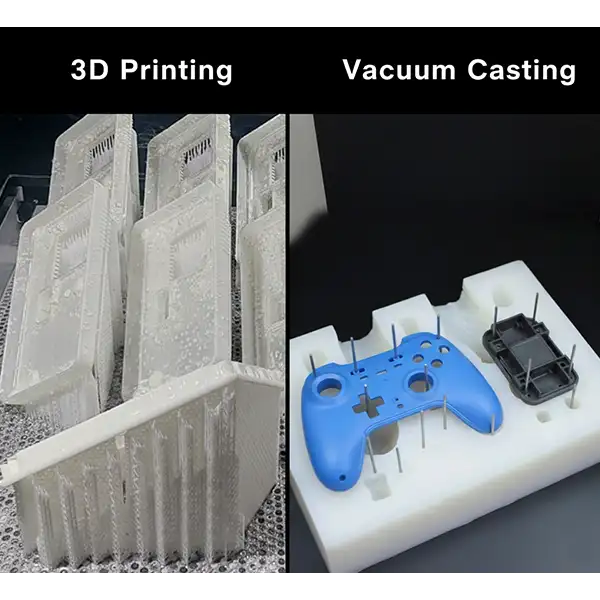

At Design Roots, we use 3D printing and vacuum casting in Mysore to make prototypes quickly and accurately. Our 3D printing gives detailed models using photopolymer resins. Vacuum casting creates strong, usable copies for testing, functional parts, and small production runs. These processes let designers and businesses move product development forward, test ideas, and produce low-volume parts efficiently.

3D Printing Services for Rapid Prototyping in Mysore

Design Roots uses Stereolithography technology to develop accurate, high-quality prototypes by 3D printing in Mysore. Our team produces reliable models for product design, engineering projects, and creative work, enabling businesses to check fit, test functionality, and refine concepts efficiently.

Other Additive Manufacturing & Prototyping Services

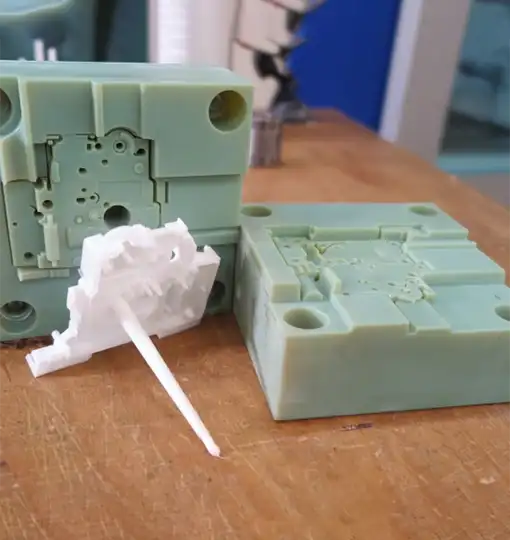

Design Roots offers vacuum casting services in Mysore, providing accurate and durable parts for low-volume production and prototypes. Using silicone molds, they replicate master models precisely, creating detailed components with smooth finishes. The process is suitable for product testing, design validation, and short-run production. It helps businesses create prototypes efficiently and at a lower cost, while helping move ideas from design to finished parts.

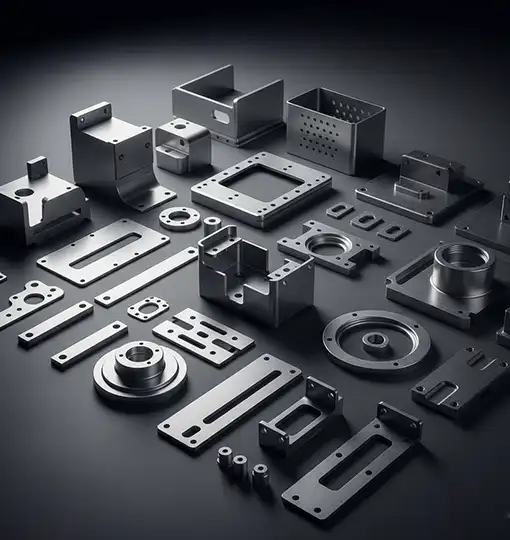

Injection Molding

Custom injection molded components with tight tolerance and reliable finish.

3D Printer & Vacuum Casting Machine for Sale in Mysore

Accelerate prototyping and manufacture custom parts with premium 3D printing solutions. Ideal for product development and engineering applications in Mysore’s industrial hubs.

Read More

Vacuum casting enables fast, accurate, and cost-effective production of high-quality patterns and low-volume parts. Perfect for automotive, pumps & motors, medical devices, and precision component manufacturers across Coimbatore.

Read More

Local Industry Insight

With strong experience in 3D printing and a good understanding of Mysore’s industrial sectors, we create precise prototypes that fit local manufacturing and testing needs.

High-Performance Systems

Using reliable 3D printing and vacuum casting systems, we deliver fast, accurate, and sturdy parts designed for consistent results on every project.

Customer-Focused Process

We believe in working closely with clients. From start to finish, we maintain open communication, dependable results, and steady support.

Complete Prototyping

We offer complete 3D printing and vacuum casting solutions in Mysore, from initial design checks to finished parts, helping teams move smoothly from concept to production.

Why Choose Design Roots for 3D Printing & Vacuum Casting?

3D Printing & Vacuum Casting Applications in Mysore

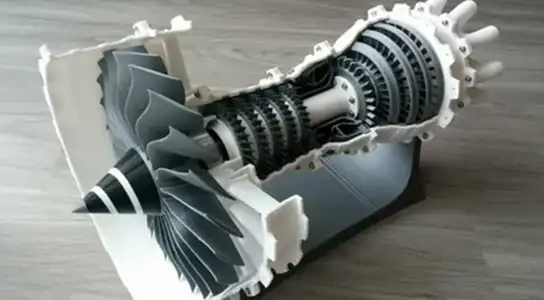

Aerospace Industry

The aerospace sector in Mysore applies 3D printing to produce precise and lightweight parts for wind tunnel and functional evaluations. Vacuum casting is used to make short-run components for design trials and pre-production.

Healthcare Industry

Mysore’s healthcare sector leverages 3D printing to craft detailed surgical and dental models for medical planning. Vacuum casting is supported by creating short-run prototypes and tool housings that aid testing and clinical assessments.

Defense Industry

The defense sector in Mysore utilizes 3D printing to create robust prototypes for design and field testing. Vacuum casting helps by generating limited-batch, robust pieces for pre-deployment inspections and operational testing.

Electronics Industry

Mysore’s electronics sector uses 3D printing to develop compact enclosures and functional prototypes for device testing. Vacuum casting supports by producing durable samples in small quantities for design review and product verification.

IT & Tech Industry

Tech and IT firms in Mysore employ 3D printing to create prototypes of gadgets and interface mockups. Vacuum casting produces short-run models for presentations and client demos.

Startup & R&D Innovators

Mysore's startups and R&D departments swiftly test and perfect their design variations using 3D printing. Vacuum casting enables them to generate tested prototypes and little trial runs that quicken development from idea to market testing or practical application.

Shipbuilding Industry

The shipbuilding sector in Mysore applies 3D printing to examine complex components for structure and durability. For design validation and performance evaluation, vacuum casting helps to create functioning, low-volume prototypes.

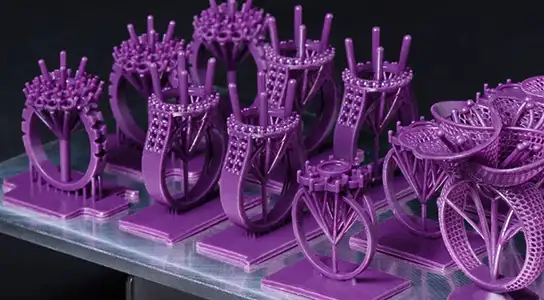

Jewelry & Design Industry

To create precise molds and elaborate designs for ornaments, Mysore-based jewelry designers use 3D printing. Vacuum casting helps to produce short-run copies and sample models that retain design elements for customer approval and production tests.

Benefits of 3D Printing & Vacuum Casting Services

Industrial zones of Mysore like Hebbal, Hootagalli, Yeshwanthpur, Gokulam, KIADB Industrial Estate, Belagola, and Bannur Road are heavily dependent on prototyping to perfect their designs and quicken the pace of the development process. 3D printing is a technique that is used to create highly detailed and smooth parts for functional testing and design validation. Vacuum casting allows small-batch production of components without tooling. Manufacturers of pumps and motors, automotive components, healthcare devices, aerospace parts, and startup products use these processes to reduce time-to-market and improve product reliability in Mysore.

Contact Us for 3D Printing & Vacuum Casting Support

We assist with choosing materials, testing designs, estimating costs, and building prototypes quickly to keep your project moving toward production.